Equipment products

New forces of intelligent manufacturing, innovation has always been on the road

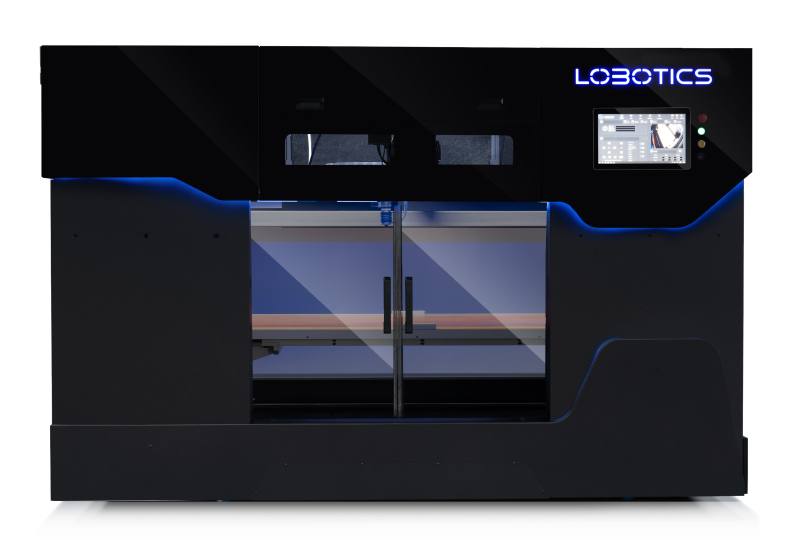

technical grade Composite 3D printing, automotive grade thermoplastic additive manufacturing equipment

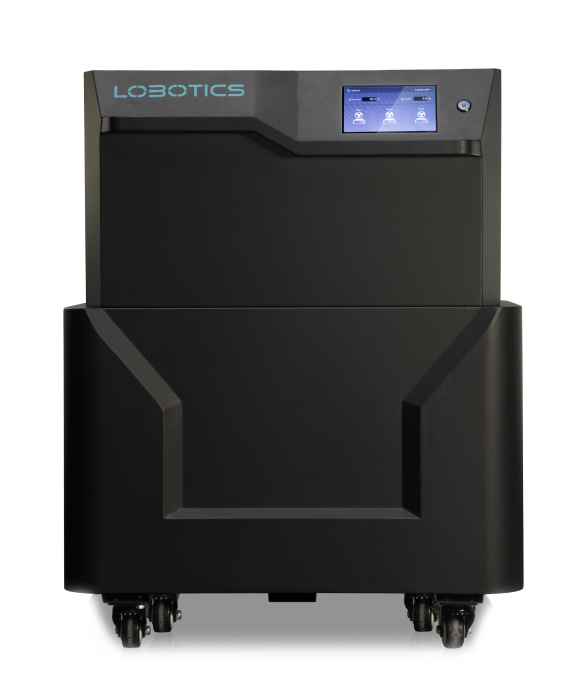

Intelligent Materials System (IMS)

High weather resistance, oxidation resistance, more stable printing process

High grinding force control accuracy, automatic alignment system

Suggested Reading

Lobotics debuted at the China Industry Fair

From August 23 to 26, 2022, Lobotics brought the latest generation of 3D printer AMPS 1200 to the Expo, in the rapid development of additive manufacturing technology today, in order to fully meet the manufacturing needs of major industries, the market's functional demand for 3D printers is also constantly escalating. At this exhibition, Lobotics showcased the latest generation of 3D printer, AMPS 1200, and also highlighted the one-stop production solution for industrial scenarios.

From mold design to composite 3D printing to production

Lobotics 3D solutions help customers move from mold design to composite 3D printing to production. Historically, the production of carbon fiber parts has been done by manually pasting carbon fiber brush resin materials on the mold to cure and demold. This traditional production process not only uses high mold costs, but also low production efficiency. By adopting the solution provided by Lobotics 3D, the customer has greatly improved production efficiency on the basis of reducing costs.

Innovation-driven, winning the Double EU Project Award (CoMetas, XS-Meta)

In line with the industry trend, Lobotics is committed to integrating the discrete manufacturing production process of the past into a one-stop end-to-end delivery production process, providing users with faster, better and more economical high-automation overall solutions. In the practice of continuous integration and innovation and deepening application, Lobotics has enough accumulation to drive the update and iteration of additive manufacturing equipment to meet the market demand for diversified development in the future.

Industry case

Automobile industry

Aerospace and aviation

Medical industry

Solution