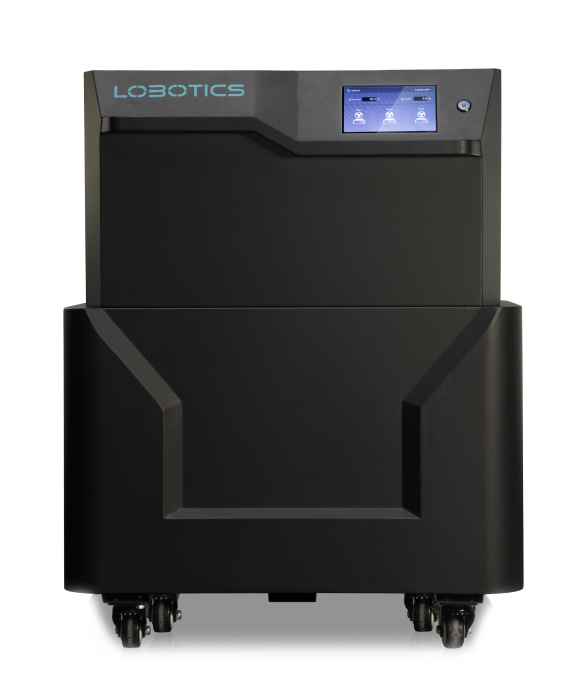

3D Printer

AMPS 1200

High precision, Efficiency, Large-size printing

Focusing on the application upgrade of 3D printing technology from prototype design to large-scale customized production, and solving a series of challenges faced by traditional additive manufacturing technology.

Product Manual | Download

Printing speed | 200mm/s

Maximum forming size | 1200x600x600mm

Printing accuracy | within 0.05mm

The unique RFC (Rapid Fusion of Composite) printing technology can fully meet the printing of large-size parts. The closed-loop ultra-high-precision linear motor design and self-developed high-performance control system monitor the entire printing process in real time.

Combined with the traditional machine tool structure, the mechanical structure design has been innovatively improved from multiple dimensions such as light weight and applicability, and the dynamic response performance of the control system has been greatly improved. In addition, the mechanical structure design of the hardware equipment not only ensures the accuracy of parts, but also improves the positioning accuracy and transmission stiffness of the machine tool.

Device parameters:

| Type | AMPS1200 |

| Printing volume | 1200x600x600mm |

| Weight | 1.6T |

| XY axis motor | High-precision closed-loop linear motor system |

| XY axis repeatability positioning accuracy | 5um |

| Leveling mode | Automatic leveling |

| Software | Self-developed host computer software memory automatic optimization other functions |

| Lower computer | High-performance self-developed control board |

| Monitoring function | Remote real-time monitoring |

| Nozzle size | 1.2mm, 1.0mm, 0.8mm, 0.6mm |

| Print speed | 200mm/s |

| Print efficiency | 5KG/day |

| Match the materials | XPET,XPET-PRO,XPA,XPA-PRO |

| Open materials | Yes |

| Material diameter | 2.85mm |

| Material storage | Material station with active drying, humidity control weight monitoring system |

| Print accuracy | ±0.1mm---±0.3mm(1mm nozzle) ±0.05mm---±0.2mm(0.6mm nozzle) |

Intelligent Material System (IMS)

High weatherability, high antioxidant,, and more stable printing process

With the support of the latest IT technology, IMS can support multiple machine control at the same time and support application integration through API. Customization according to user requirement, connection between materials and equipment, and IOT technology make 3D printing technology more mature and industrialized.

Intelligent Material System (IMS)

- Intelligent Material System (IMS), mainly used for active drying of printing materials, these materials are hygroscopic, keeping engineering grade materials dry is especially important in the production process. The IMS is equipped with a temperature and humidity sensor and a weight monitoring system, which can keep the material in a dry state and ensure that the humidity of the entire environment is below 10%.

- In addition, it is also equipped with an intelligent detection system. During the printing process, if the material is blocked or broken, the IMS will feed back the status of the nozzle to the host computer system, so as to guide the next step of operation.