MES

AMES System

Observing the printing process in real time and print intelligently

- Monitor the printing process

- Collect data in real time

- Data visualization

- Cloud intelligence

- Unmanned production

- Improve print quality and efficiency

AMES System

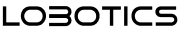

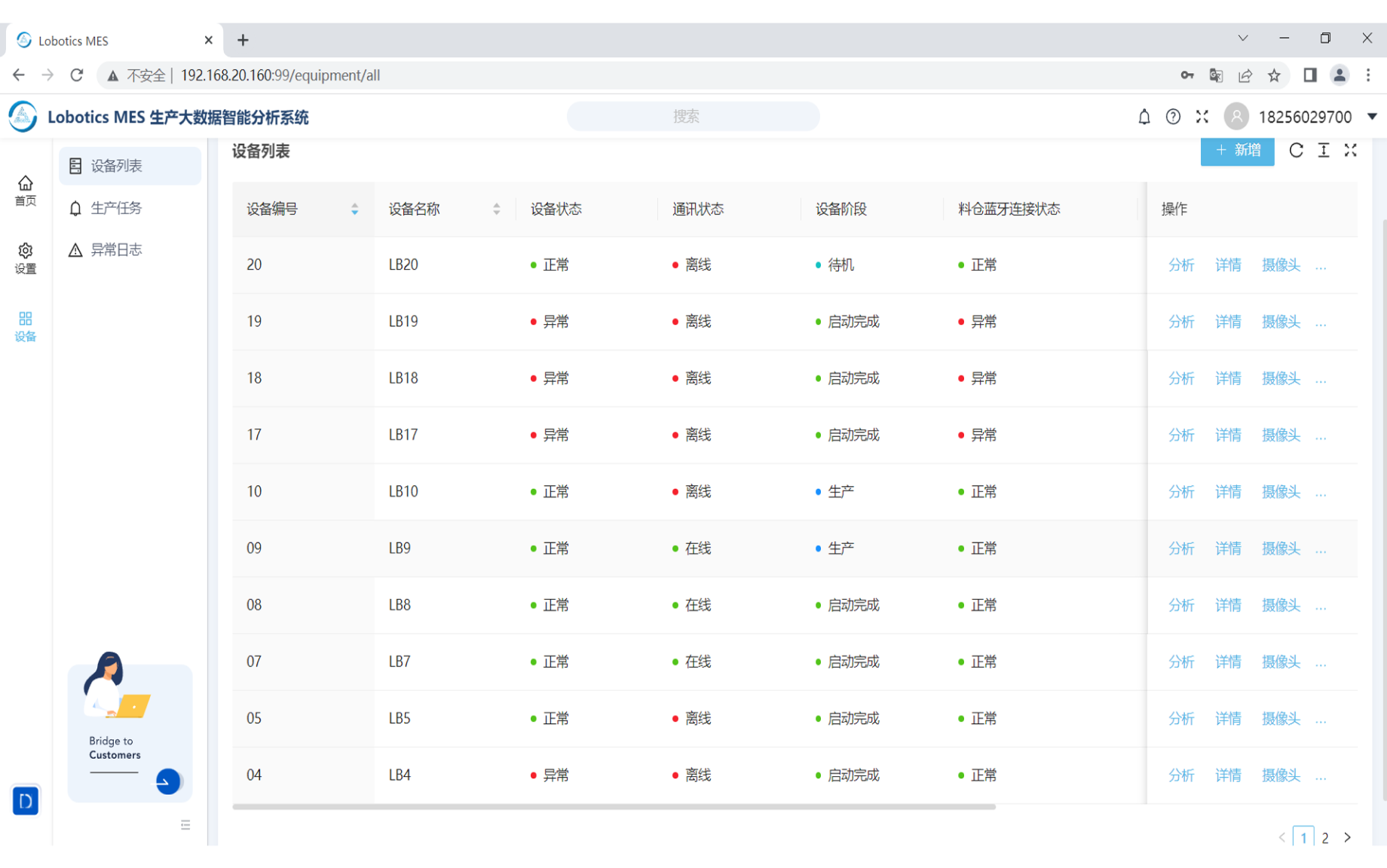

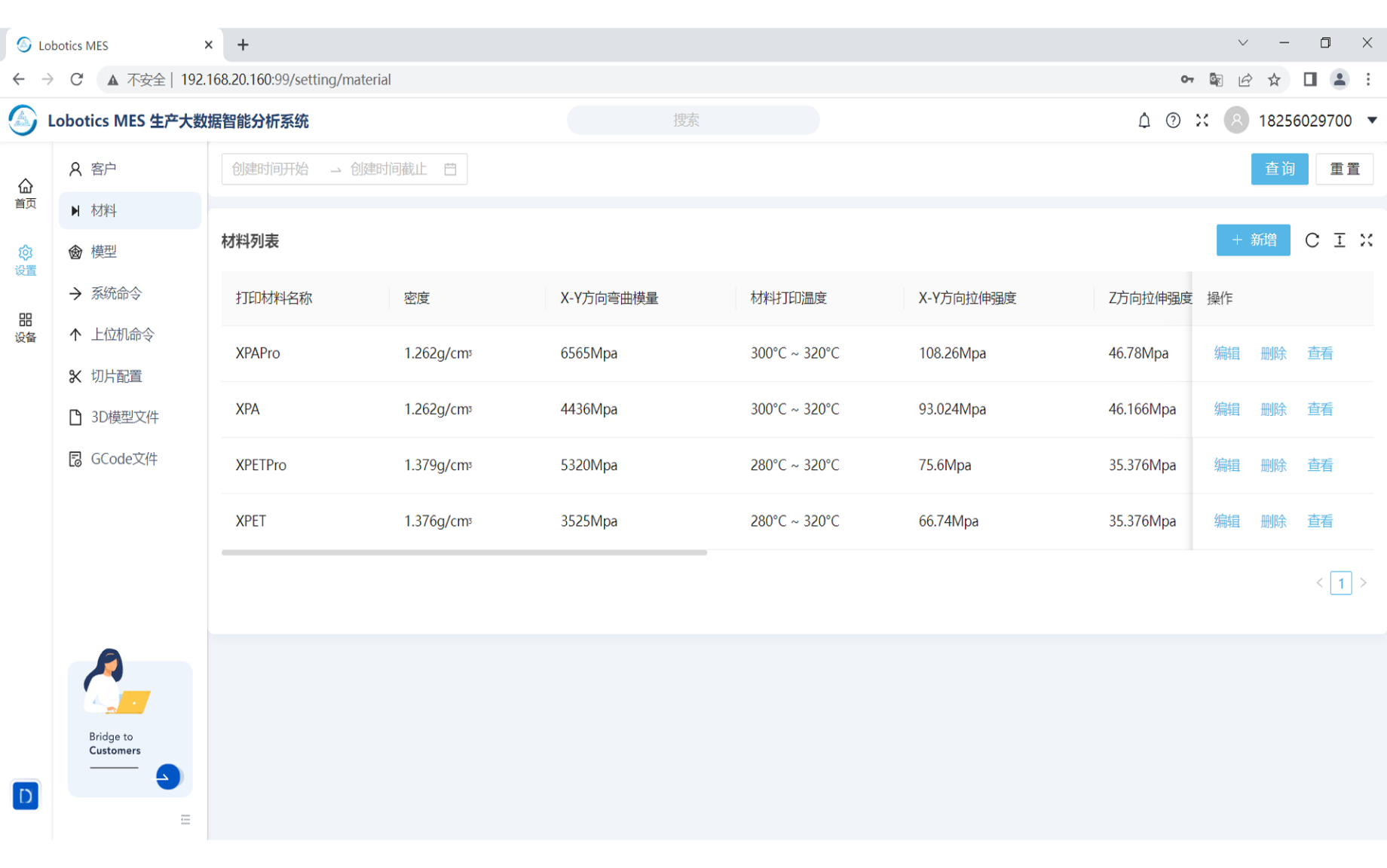

AMES system using the latest technology stack, can support multiple machine control at the same time, and support application integration through API. Customization based on user information, connection between raw materials and equipment, cloud data collection of smart devices, making 3D printing technology more mature and industrialized.

Visualization Printing

- Through camera monitoring, offline and remote access to the camera can be realized to observe the printing status so that engineers can make corresponding judgments.

Real-time, high stability

- In order to match the high-speed printing of the equipment, the system is equipped with a high-performance host to achieve multi-threaded and stable printing.

Silo monitoring

- By monitoring the status of the silo in real time and reporting early warning information in a timely manner, the integrity of parts printing is ensured; in addition, by detecting the temperature and humidity information of the silo, it can provide data reference for parts quality evaluation.