Lobotics 3D printing solution helps CETC Diamond Aircraft toward production from mold design to composite 3D printing. The production of carbon fiber parts has been done by handmade, paste carbon fiber and brush resin material on the mold, then cure and demold. The efficiency of such traditional process is poor, and it requires costly mold. After adopting the solution provided by Lobotics 3D printing, CETC Diamond Aircraft has greatly improve production efficiency with declined costs.

3D printing adaptive design

Generally, the printing model provided by the supplier is designed according to the traditional manufacturing. If the model is directly printed by FDM 3D printer, it might be difficult to remove the support, the surface quality is not high, and the error is too high to assemble. Before Lobotics 3D printing, the process engineer will slice the model and simulate printing. If any of the above problems are found, the message will send to structural designer. The structural designer will adjust the model structure according to the characteristics of FDM 3D printing process, and then the process engineer will slicing and printing again for the modified model.

.png)

3D printing composite mold

The XPET-PRO material used in Lobotics 3D printing has satisfied the using temperature (the maximum service temperature can reach 120 ℃) and mechanical performance of the mold. After remove the redundant support, simply polished and constant temperature annealing, the printed mold prototype it can trial assembly. Through the surface post-treatment, a relatively ideal product mold can be obtained.

.png)

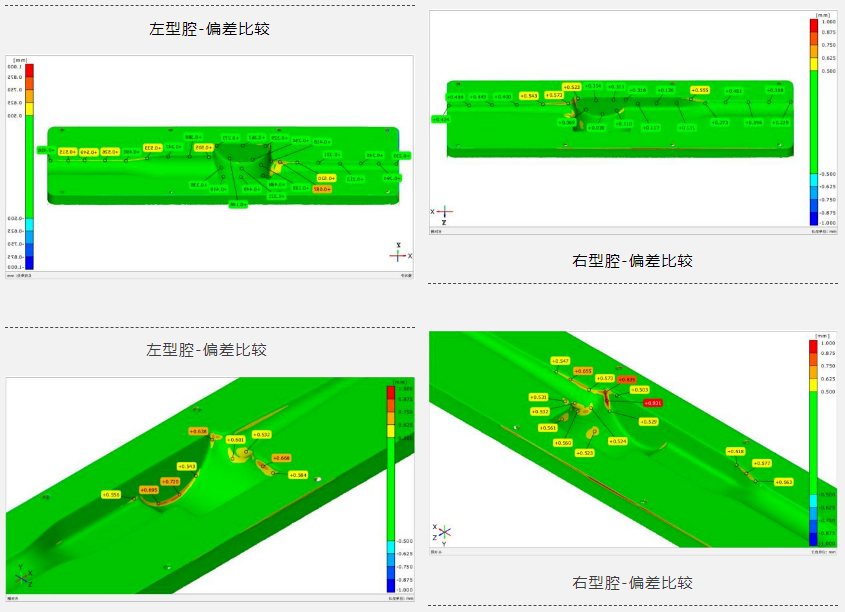

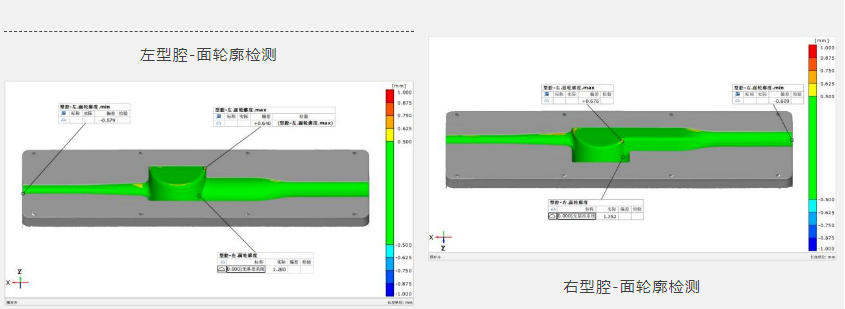

3D scanning qualification of mold

The composite mold before deliver to our customer will be qualified through 3D scanning and generated a report for checking by Lobotics.

Production of carbon fiber composite mold

Customers use the Lobotics 3D printing composite mold for production and get good carbon fiber products.

.png)

Lobotics 3D printing composite mold satisfied the relevant standard and use requirements. CETC Diamond Aircraft highly appreciated the Lobotics 3D printing solution and strengthened the strategic cooperation relationship. Lobotics will continually participate in the development of new projects of CETC Diamond Aircraft, and our team will also enhance our technical advantages from practice.