industry: Advantages of 3D printed vehicle components

The continues development of automobile industry requires to incorporate new technologies whereas the technologies in the vehicle production are highly complex, which makes automobile industry challenging the competition between the traditional and new technologies, and high technical threshold. Automakers and suppliers are interested in the technologies which can effectively reduce costs and satisfy their can meet their strict standards for quality, safety, production efficiency and mass production as well as the increasing demand for personalization and customization.

From automotive industry and its products to today's intelligent manufacturing systems, the complexity is extremely high. Additive manufacturing has great potential to simplify the entire processes from designing to production so that can improve efficiency with reducing costs, which is impossible to be achieved by traditional manufacturing. At present, this technique is used to rapidly produce lighter, multi-material components with better functionality, fewer design constraints, and more complex geometric designs. The characteristics of additive manufacturing make it will have less scrap and overall material consumption, which is important when using costly advanced materials. In addition, additive manufacturing requires less post-processing of the production of components compare to the conventional.

Efficiency, quality and cost are the main factors driving production decisions. Additive manufacturing makes customized components to be simply and precisely produced with reducing cost. In the automotive industry, the application of lighter 3D printed components has significantly reduced the weight of the vehicle, which is a breakthrough of lightweight vehicle structural design. From the perspective of the entire production process, additive manufacturing directly improves the general efficiency and complies with the environmental protection trend of sustainable development. In the era of carbon neutrality, emission peak, and personalized customization, 3D printing is the best novel technology that meet the needs of end users in automobile industry. Meanwhile, the costs can be reduced and the lead-time will be shorter by using 3D printing in the production of fixtures or auto parts that require quick replacement. Thus, additive manufacturing is in line with the development strategy of automotive manufacturing. In the long term, additive manufacturing will be more widely used in mass-production.

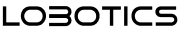

Customer Case --- 3D printing in customized mass production

Total solution providers from design to manufacturing

The design purpose of Lobotics’ total solution for additive manufacturing is to combine our services with the production, related design and modeling process of manufacturing enterprises and allows them to fully use the advantages of additive manufacturing from the early stage of research and development. Our total solution can solve the inconvenience in design, 3D printing, post-processing processes of other additive manufacturing solutions, which contains different service providers for each step. Furthermore, our solution can help manufacturers greatly improve their efficiency, creativity and flexibility and dig the profit points of applying additive manufacturing technology from design to production. Thus, our customers can minimize the cost and lead-time of the their product.

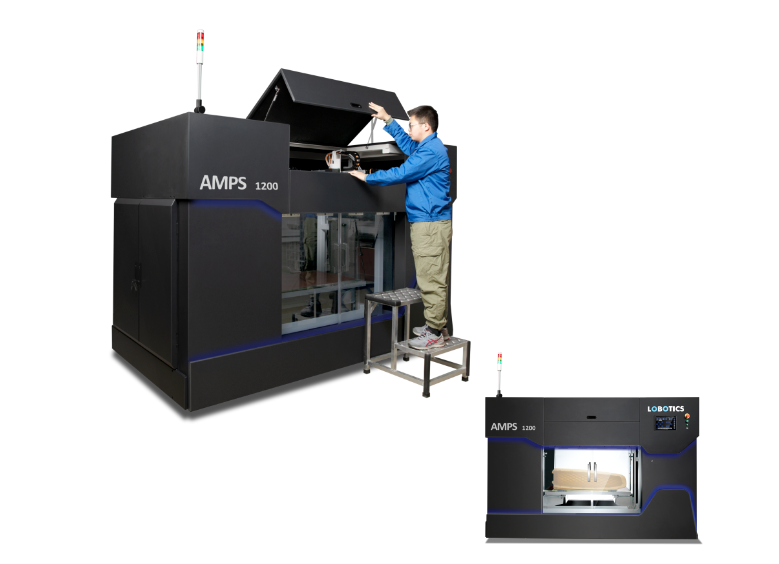

Produce more precise and uniform samples

In Lobotics 3D printer, the dynamic response performance of all feedback control systems is greatly improved by directly declining the response time of partial mechanical transmission components. The mechanical structure designs of the 3D printer developed by Lobotics are not only improves the positioning accuracy and transmission stiffness of the machine tool, but also controls the feeding of raw materials more precisely, which is a better the transmission mode from several aspects compare to other suppliers. All the ingenious mechanical design has made our industrial 3D printer achieve unprecedented accuracy and uniformity of printed product during high-speed printing.